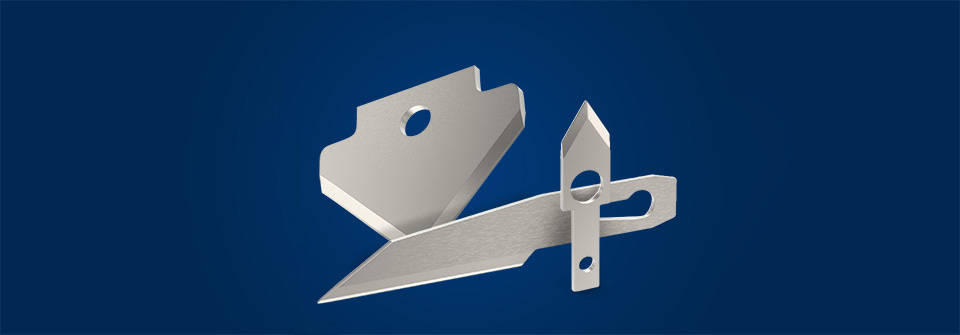

Pointed blades

by LUTZ BLADES

Pointed blades

by LUTZ BLADES

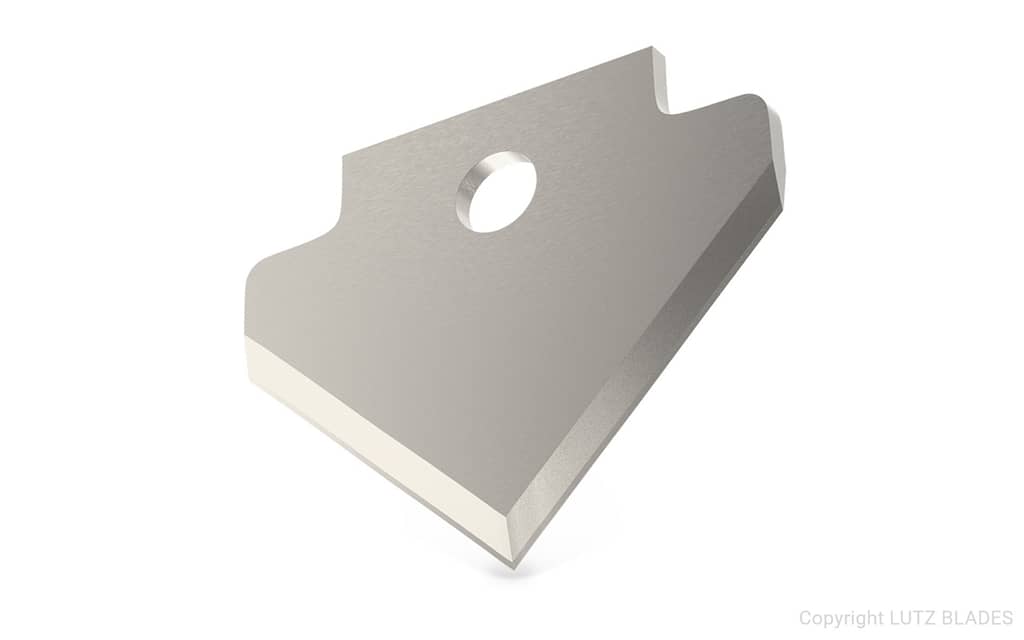

Blades for surgery and precision cutting in industry

LUTZ BLADES pointed blades are among the best on the market. Thanks to their high quality, our pointed blades are used in various cutting processes such as surgery or processing plastics or leather.

Product recommendation

5798

Completed Orders

15

Qualified Engineers

5+

Work Facilities

3+

Worldwide Branches

The wide range of materials for our blades

Our product portfolio offers you blades in thicknesses between 0.06 – 3.0 mm and with final hardnesses between 40 – 85 HRc. You also have a wide choice in our material program:

The versatile coating program

for our blades

TiN

Standard hard material with high wear resistance and relatively high coefficient of friction (against reference material steel approx. 0.4 to 0.7), usually gold-colored, safe application range up to approx. 300 °C.

TiAlN

Has greater oxidation resistance than TiN with comparable coefficient of friction, usually anthracite blue.

Blueing / Blackening

Applied over the entire surface, light corrosion and starch protection, also serves as a distinguishing aid.

Teflon® (PTFE)

Teflon® non-stick coating (PTFE); due to the very low surface tension, practically no foreign bodies stick to the cutting edge, resistant to acids and alkalis; significantly reduced frictional resistance; the very low static friction allows jerk-free cutting (therefore very suitable for the medical sector); low wear resistance; not suitable for contact with sodium and at temperatures above 250 °C.

TiC

Has lower wear resistance than TiN with significantly lower coefficient of friction (against reference material steel approx. 0.3 to 0.5), usually anthracite colored.

ZrN

With a wear resistance similar to TiN, but denser structure (morphology) than TiN and thus greater resistance to pitting under appropriate load, usually steel colored.

CrN

Has lower wear resistance than TiN. Advantage of CrN: lower residual stresses than TiN. Therefore partially useful for applications with high bending load.

TiCN

Intermediate coating material between the high wear resistance of TiN and the low coefficient of friction of TiC, relative position between TiN and TiC depending on the ratio of C and N, usually anthracite color.

DLC

Has high wear resistance with low coefficient of friction (approx. 0.1 against reference material steel); susceptible to impact loads and high temperatures (between 100 and 300 °C depending on structure).

Color varnish

Applied over the entire surface, serves as a sorting aid for different material thicknesses and as corrosion protection.

Customized quality

Do you need a blade that is tailored to your individual cutting process? Which, even if produced in small quantities, has a near-series quality? Our development department has the right answer to these questions: prototype production by LUTZ BLADES.

Do you have individual wishes?

Do you have a question? A concern? Or a suggestion? Do not hesitate to contact us. We have the right experts for all matters, who can help you with certainty.

How can we help you?

We are pleased if we can be of further assistance to you